Dynamic Balancing

Machines

Seltrade

Schenck Partner

Seltrade supplies a focused lineup of Schenck RoTec workshop balancing machines and portable handheld analyzers, designed for precise rotor balancing across industrial, HVAC, automotive, and aerospace applications. These systems support everything from small workshop tasks to mission-critical balancing jobs.

Features & Benefits

- High-precision balancing capabilities for a wide range of rotor weights and sizes.

- State-of-the-art measuring technology enabling minimal residual unbalance (e.g., < 0.5 gmm per plane for PASIO 50).

- Modular product range from small workshop machines (PASIO 5) to full-scale production lines (PASIO 50) covering manual to automated solutions.

- Localised support in the GCC – supply, calibration, training and parts.

- German engineering heritage and global brand reliability.

Applications

- Balancing of rotors in manufacturing: fans, blowers, compressors, electric motors, armatures.

- Maintenance and repair workshops handling small to medium-sized rotors.

- OEM assembly lines requiring high throughput balancing solutions.

- On-site balancing for large assemblies in industrial plants (e.g., power generation, HVAC, maritime).

- Quality assurance & test centres where precise dynamic balancing is mission-critical.

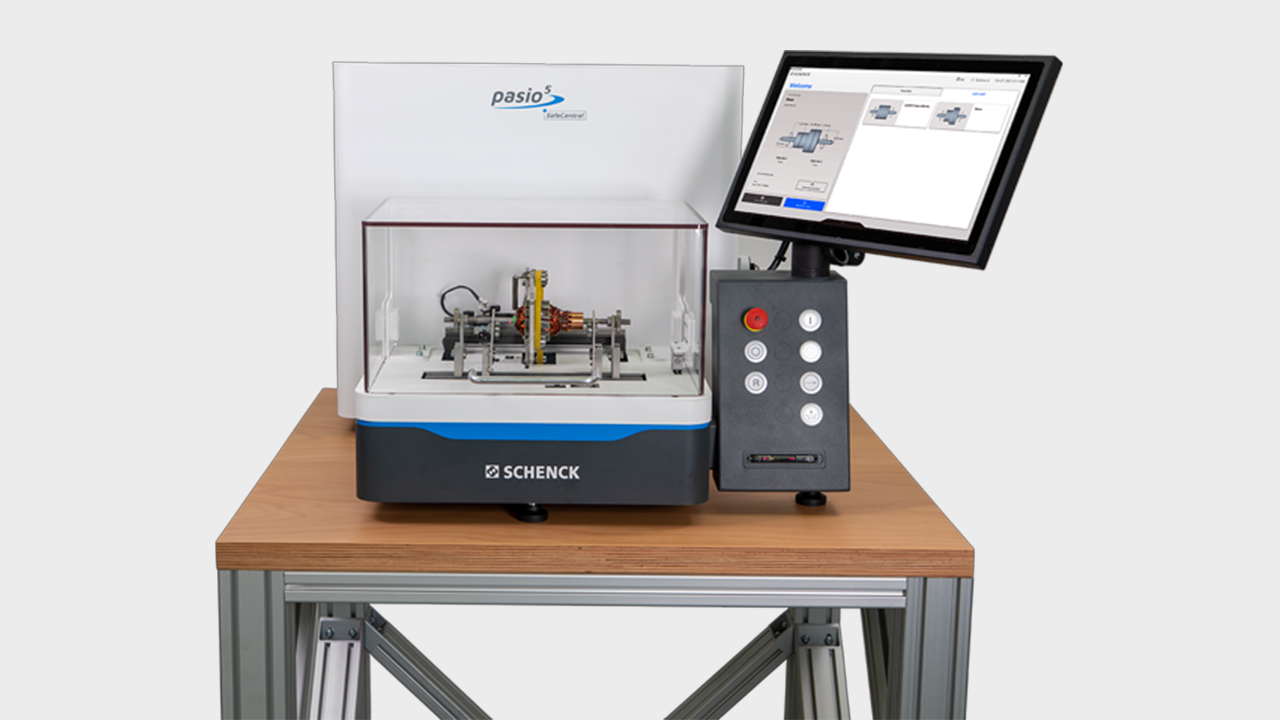

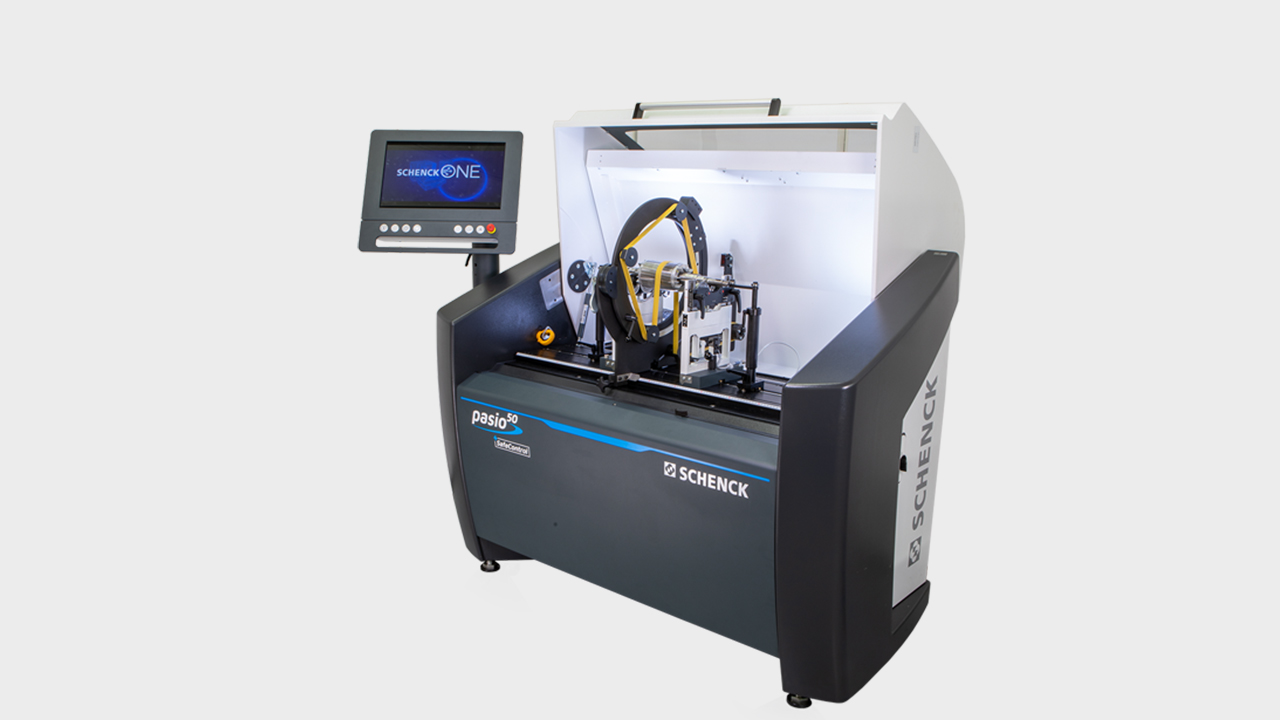

PASIO Series

Compact, precision balancing machines designed for small to medium rotors. Ideal for workshops, small production lines, and electric motor repair centers. Supports a wide variety of rotor shapes with high measurement accuracy.

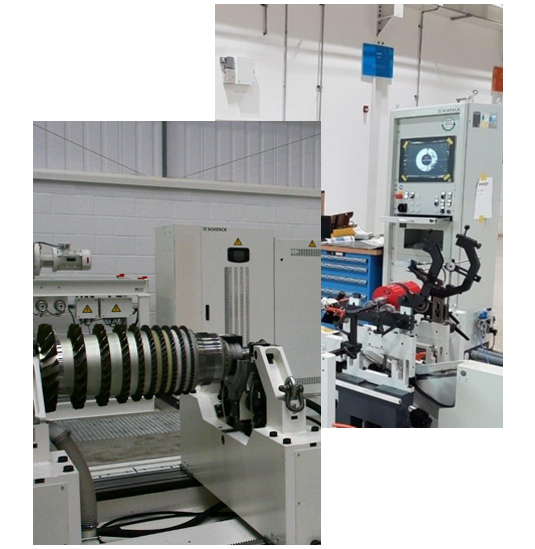

HM Series

Heavy-duty balancing machines engineered for larger industrial rotors with higher load capacity. Robust construction makes them suitable for industrial plants, service workshops, and general maintenance environments requiring reliable manual balancing.

VIRIO Series

Flexible, modular machines designed to accommodate a broad range of rotor types and sizes. Perfect for production environments needing adaptable balancing capability with efficient setup and repeat results.

DH Test Facilities

High-speed test rigs designed for R&D laboratories and prototype testing. Ideal for measuring rotor dynamics at elevated speeds, used when precision rotor behavior and vibration characteristics must be accurately evaluated.

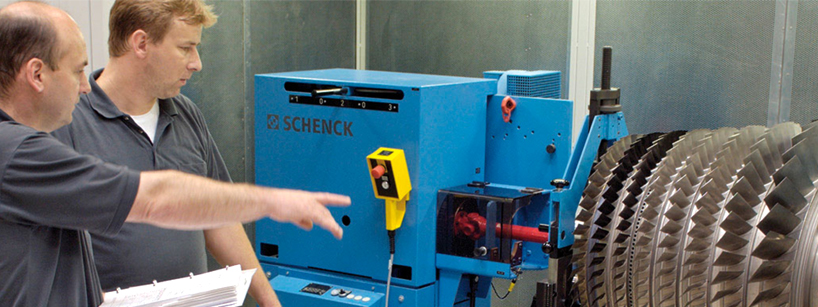

Airlines & Aerospace Systems

Dedicated balancing solutions developed for aviation-grade rotors, including turbines and precision aerospace components. Built to meet stringent standards for safety-critical applications.

TARO & ESx Machines

Universal balancing machines for production and maintenance facilities, offering high repeatability, simplified operation, and a wide rotor compatibility range. Suitable for both small workshops and medium industrial production.

SmartBalancer 4

Portable field-balancing tool for on-site balancing of machinery without dismantling. Ideal for fans, pumps, motors, blowers, compressors, and HVAC equipment.

Smart VibroAnalyzer 90

Compact vibration analyzer for quick assessments of unbalance, misalignment, bearings, and general machine condition. Supports preventive maintenance routines.

Smart VibroAnalyzer 95

Advanced handheld analyzer offering route-based measurement, deeper vibration diagnostics, and high-precision field balancing. Designed for predictive maintenance and industrial reliability teams.

Schenck One – Digital Solutions

From stand-alone solutions to networked machine pools – we help you to use process analyses, error reduction, and predictive maintenance to improve the balancing process. Schenck ONE is Schenck’s new digital brand that makes your balancing-related processes more transparent. These intelligent software solutions are used to collect data that serves as a basis for optimized processes and maximum quality.

Visit Schenck